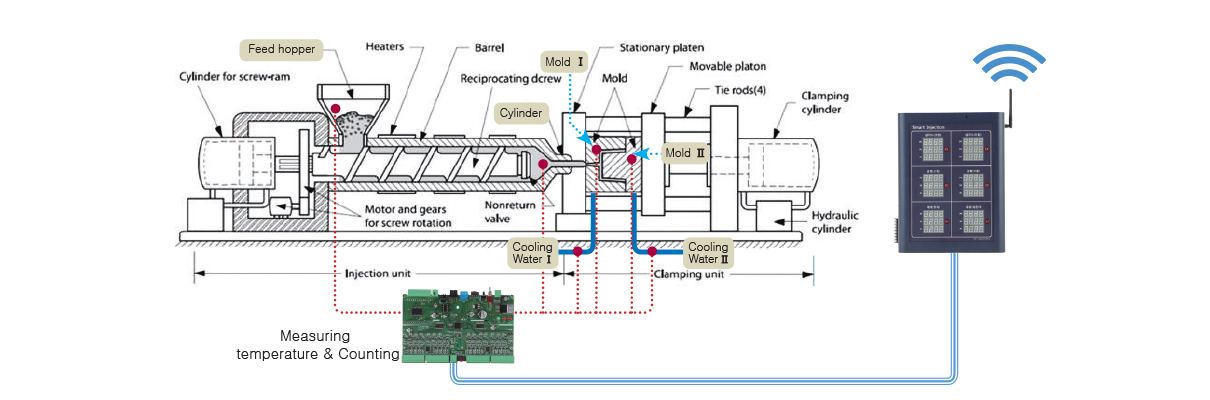

| Step#1 | Real time, Measuring and saving the temperature of molds, cooling water, hopper, cylinder, oil. |

| Step#2 | The temperature of the ending stages of all manufactured model is automatically saved as the well made product temperature of each product model. |

| Step#3 | The above temperature of the ending stages is automatically set up, when changing manufacture model. |

| Step#4 | Real time, Measuring and saving the product count and defective product count with the cause of defect. Real time, Input the unavailable status of the machine with the cause of unavailable status. * option : DAQ Button |

System Integration